| Materials & Construction Techniques |

WesPac Pipeline Systems |

PG&E San Bruno |

Benefits |

| Technology of construction |

2010 |

1950s |

Most modern, state-of-the-art materials and techniques. |

| Ability to use pig for internal inspection |

Yes |

No |

This technology allows for early detection of problems such as corrosion and damage to the pipeline’s system from third party construction damage. |

| Ultrasonic sensors detect breaks |

Yes |

No |

Sensors detect metal loss. |

| Constant diameter pipeline |

Yes |

No |

Constant diameter allows the use of pigs for internal inspection. A multiple diameter pipe does not readily allow the use of pigs due to inability to move from one end of the system to the other. |

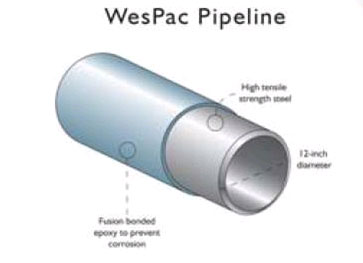

| High tensile strength steel |

Yes |

No |

The strength of the steel has increased tremendously over the years. The typical pipe strength in the 1950s was 36,000 to 42,000 psi. Today’s high tensile strength pipe steel is between 52,000 to 70,000 psi. |

| Improvements with epoxies, polyethylene, polyurethane and improved adhesives for coating of pipeline |

Yes |

No |

In the 1950s, the typical external pipe coating was coal tar and often installed in the field when the pipe was being installed in the pipeline trench. Today’s modern coatings are significantly better in protecting the pipe from external corrosion and have higher quality controls during the installation process, which is done at coating plants in controlled environments. |

| Longitudinal welding of seam is stronger and higher quality |

Yes |

No |

Today’s modern pipelines are manufactured at pipe mills with more sophisticated manufacturing processes and higher quality control, including ultrasonically testing the longitudinal pipe seam for detecting possible defects. |

| Welding rod for butt welding is stronger and quality controlled tested |

Yes |

No |

WesPac’s policy is to 00% x-ray all butt welds (joining of two separate pipes). Historically, older pipelines only x-rayed 10% on these butt welds. |

| New Quality Controls |

WesPac Pipeline Systems |

PG&E San Bruno |

Benefits |

| Testing for defects in the external coating used for corrosion protection |

Yes |

No |

Allows us to find defects in the coating before pipe is placed in the ditch thereby preventing a localized area for external corrosion to impact the pipeline. |

| Improved quality control of steel manufacturing |

Yes |

No |

As a result of improved steel manufacturing, the welding of the steel is much better; therefore can withstand pressure issues. Pipe manufactures must meet the defined specifications of API for metallurgy and manufacturing processes which are specified in all oil pipeline operators’ purchasing contracts. |

| More field inspection required |

Yes |

No |

Over the last 20 years, the Federal and State Government have required more frequent field inspection. Pipeline operators through their respective right-of way protection programs prevent third party damage to their pipelines. |

| Handling of Pipe at Installation |

Nylon slings, fiber belts, padded clamps, vacuum lifts and jacking pads |

Wire cables and hooks |

New tools used to handle the installation protect the coating of the pipe, thereby protecting the pipe from damage which was caused by the older tools. This protection ensures the quality of the external coating in order to protect the pipe from external corrosion. |

| Protective Coatings applied at plant in a controlled atmosphere |

Yes |

No |

Applying coating at plant allows for a strong bonding of the coating to pipe. Prior coating over the ditch allowed outside elements and weather conditions to impact the coating which resulted in weak bonding of the coating to the pipe and an area to allow moisture, etc. to begin externally corroding the pipe. |

| Pipe thoroughly cleaned prior to plant applied coating |

Yes |

No |

Acid washed, rinsed and then heated to insure dryness and grit blasted when required. Allows for stronger bonding of the coating to the pipe and prevents external pipeline corrosion. |

| Improved products for coating pipe at the weld joints |

Yes |

No |

Shrink sleeves consists of a cross-linked polyolefin backing, coated with a protective heat sensitive adhesive which effectively bonds to steel substrates and common pipeline coatings. Two-component, 100% solids epoxy coatings for direct-to-steel application providing superior corrosion protection on field applied girth-weld joints of FBE coated pipelines. |

| Safety & Monitoring Requirements |

WesPac Pipeline Systems |

PG&E San Bruno |

Benefits |

| DigAlert Notifications |

Yes |

Yes (Did not exist until late 1980s) |

One call center that has centralized information about the location of underground infrastructure. Before any operator begins a project that requires digging, they must contact DigAlert. |

| Increased Non-destructive Testing |

Yes |

No |

Today’s modern pipelines have more sophisticated manufacturing processes and higher quality control, including ultrasonically testing the longitudinal pipe seam for detecting possible defects and 100% x-ray of all butt welds. |

| Operator Qualification Testing |

Yes |

Yes (Did not exist until early 2000s) |

Assists in minimizing human error as part of any pipeline incident. Requires training and testing of all personnel involved with DOT mandated tasks for maintenance, and operation of Hazardous Liquid Pipelines. Enforced by DOT. |

Below is a table detailing some of the differences between the PG&E natural gas pipeline, and WesPac’s proposed project, as well as additional information on the benefits of new materials & techniques, quality controls, and safety & monitoring requirements.

Below is a table detailing some of the differences between the PG&E natural gas pipeline, and WesPac’s proposed project, as well as additional information on the benefits of new materials & techniques, quality controls, and safety & monitoring requirements.